Within the completion program of an E&P operator, the procedural water demand required often calls for significant infrastructure. Large volumes of water per completion often require a network of water wells, frac pits, aboveground storage tanks (“ASTs”), pumps, and transfer pipe, which can be spread over large geographies, multiple leases, and varying water sources.

Challenge

One such example of this complicated network comes from a major operator in Pennsylvania. After acquiring third-party assets and acreage, this operator found themselves with over 20 frac pits, ranging in size from 50,000 barrels to over 150,000 barrels, spread out over an expansive leasehold. The operator estimated the volume of water for each asset based on aged engineering specifications. The operator discovered that the engineered design had been altered over the years, the pits had unknown volumes of water still in storage from earlier activity, and the water itself varied in levels of quality and clarity.

Solution

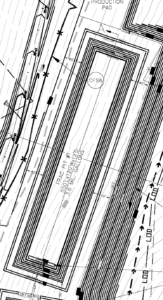

Select was hired to give a volume analysis of each water asset. Utilizing the Hydrographic Mapping Vessel (“HMV” figure 1) and the Remote Pit Monitoring (“RPM” figure 2) components of AquaView®, Select was able to create hydrographic maps of each frac pit to decide the existing and potential volumes.

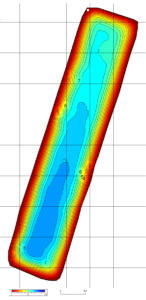

The HMV is equipped with a combination of sonar and global positioning technologies to accurately measure the capacity of the pits and give data for the RPM units. The results of the HMV data gathering are a three dimensional model of the impoundment, which is then used to calculate the static volume of the water. The associated data from this model can also be used to gain information on the potential capacity limits of the storage being mapped. RPM units are installed after the mapping process and use a vented pressure transducer and telemetry system that delivers data from the sensor, via satellite, to Select servers for display on the user’s report page.

Result

With AquaView®, Select discovered there was a 35% difference in full-capacity engineered volume and the mapped volume at full capacity (figures 3 & 4). In some cases, Select has identified variances more than 50%. The operator’s water supervisor, now armed with an accurate water inventory and real-time data monitoring, is able to communicate to people within the organization and to the necessary water transfer operators the exact volumes of water in storage before, throughout, and after the well completion.

For more information about AquaView®, click here to contact an experienced member of our team.