Case Study: Select Energy Services Reduces Methane Emissions During Drillout Process

Permian Region

The Challenge: During the drillout milling process, inconsistent and low gas rates result in non-efficient waste gas destruction through vertical pipe flares where flow lines are unavailable. Incomplete combustion of hydrocarbons can result in the emission of heavier gases, including methane, which may have a higher greenhouse effect than carbon dioxide. Select teams were already providing flowback services to customer locations in the region and finding a solution to this challenge would help the operator make significant advances in their ESG goals.

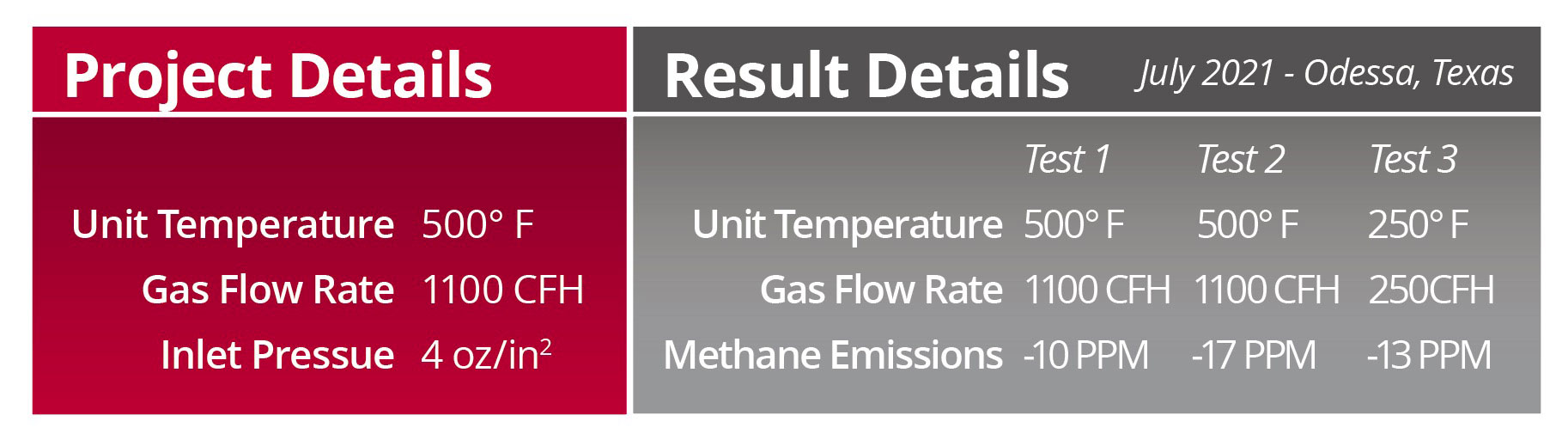

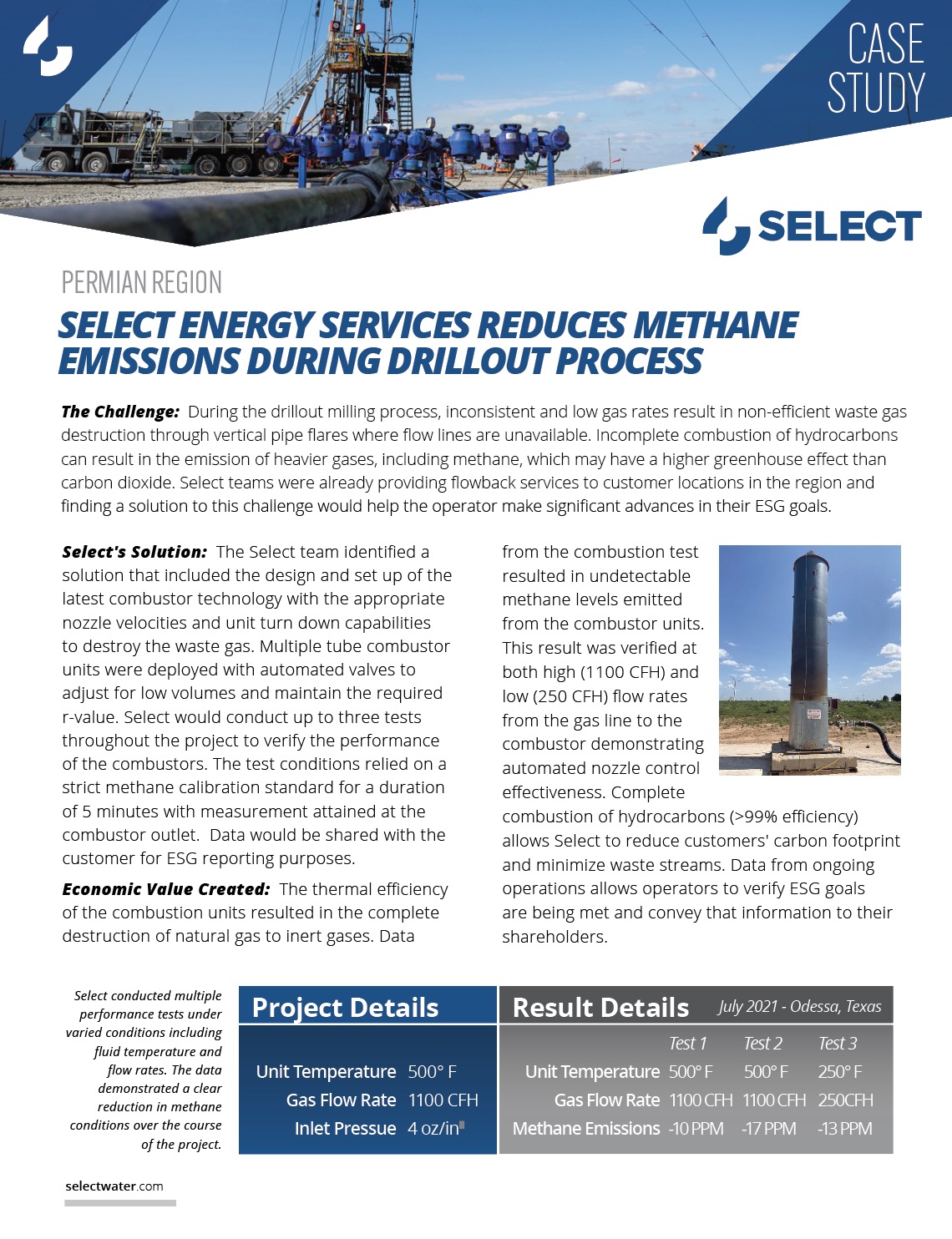

Select’s Solution: The Select team identified a solution that included the design and set up of the latest combustor technology with the appropriate nozzle velocities and unit turn down capabilities to destroy the waste gas. Multiple tube combustor units were deployed with automated valves to adjust for low volumes and maintain the required r-value. Select would conduct up to three tests throughout the project to verify the performance of the combustors. The test conditions relied on a strict methane calibration standard for a duration of 5 minutes with measurement attained at the combustor outlet. Data would be shared with the customer for ESG reporting purposes.

Select’s Solution: The Select team identified a solution that included the design and set up of the latest combustor technology with the appropriate nozzle velocities and unit turn down capabilities to destroy the waste gas. Multiple tube combustor units were deployed with automated valves to adjust for low volumes and maintain the required r-value. Select would conduct up to three tests throughout the project to verify the performance of the combustors. The test conditions relied on a strict methane calibration standard for a duration of 5 minutes with measurement attained at the combustor outlet. Data would be shared with the customer for ESG reporting purposes.

Economic Value Created: The thermal efficiency of the combustion units resulted in the complete destruction of natural gas to inert gases. Data from the combustion test resulted in undetectable methane levels emitted from the combustor units. This result was verified at both high (1100 CFH) and low (250 CFH) flow rates from the gas line to the combustor demonstrating automated nozzle control effectiveness. Complete combustion of hydrocarbons (>99% efficiency) allows Select to reduce customers’ carbon footprint and minimize waste streams. Data from ongoing operations allows operators to verify ESG goals are being met and convey that information to their shareholders.